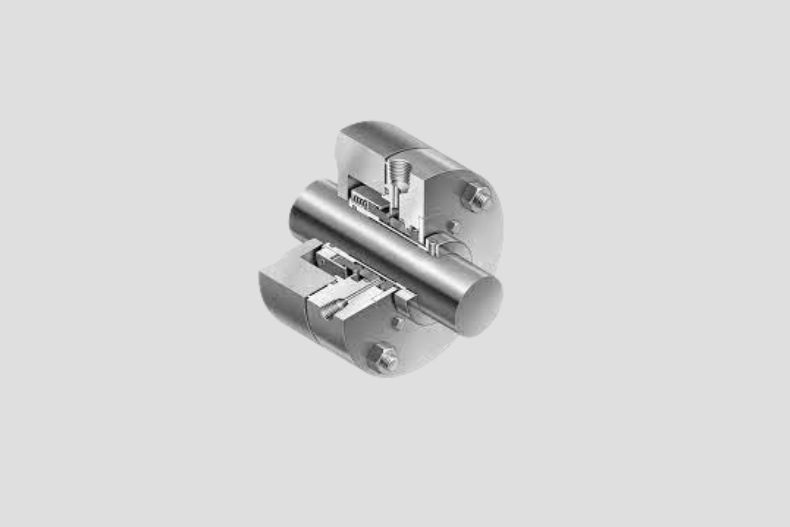

US 1008/1007 (Pusher Seal for Pumps, Single Acting Balanced Design)

The US Series 1008 and 1007 seals are engineered specifically for high-pressure pump applications. They are compact in design, so they are compatible with all types of centrifugal pumps. The easy construction makes it easy to install and maintenance-free.

These seals are available in both O-Ring and Wedge configurations for secondary sealing. The components are interchangeable, so a 1008 can be changed to a 1007 without any fuss, simply by changing the seal ring and secondary seal. Stock rationalization is the aim of this series, and it is sure to help reduce inventory management complexity.

Features

-

Independent of direction of rotation

-

Back-up ring design to avoid extrusion at high pressure

-

PTFE Wedge secondary sealing available for universal chemical compatibility

-

Designed for compact space

Operating Range

-

Pressure: 25KG

-

Size: 25mm to 150mm

-

Temp: Upto 240°C

-

Speed: 2900 rpm

Products FAQ`s

Mechanical seals are devices that prevent the leakage of fluids (liquids or gases) between a rotating shaft and a stationary element in equipment such as pumps, compressors, and mixers. They improve the operation efficiency, reduce costs on maintenance, and provide long equipment life by keeping out contaminants and maintaining the process integrity.

The choice of a mechanical seal depends on factors such as the type of equipment, fluid properties (temperature, pressure, and nature), application conditions, and industry standards. Our team provides detailed application engineering support to recommend the best solution tailored to your needs.

Depending upon operating conditions, material compatibility, and maintenance practices, the service life of a mechanical seal will vary. In optimal operating conditions, our seals have been designed to deliver reliable performance over time. In-service inspection and proper installation are also used to enhance service life.

Yes, we specialize in designing and manufacturing custom mechanical seals to meet a specific application requirement. On top of that, experts are available for troubleshooting serious sealing problems to ensure smooth-running operation.