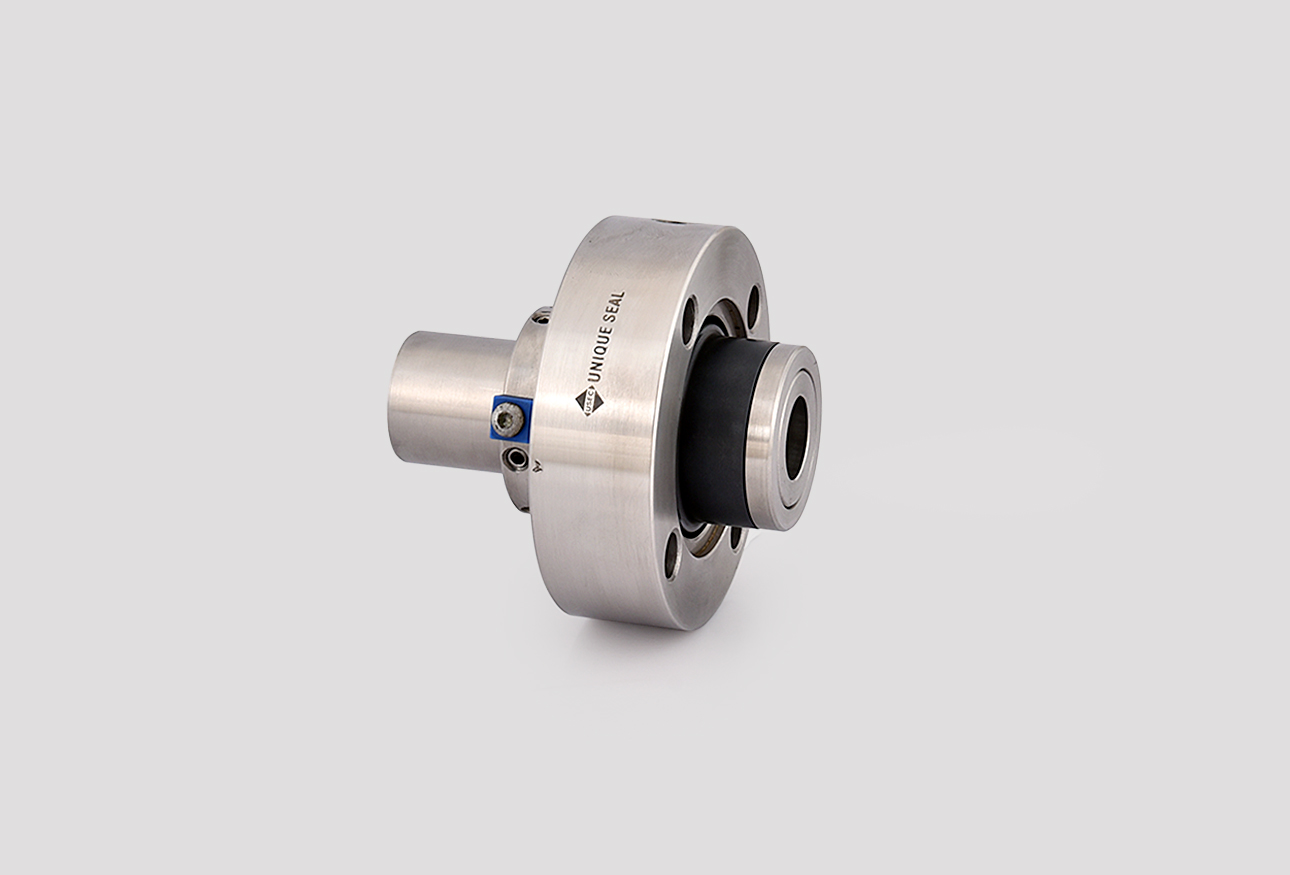

Single Cartridge Seal US 5008

Single Cartridge Seal US 5008

The Single Cartridge Seal US 5008 is one of the high-performance mechanical seals used in many industries. It is designed to be very reliable and efficient, pre-assembled in a cartridge form that reduces installation time and minimizes downtime. Such a seal is ideal for application in pumps, mixers, and agitators for leakage management and prevention of contamination.

Constructed from strong material, the US 5008 is highly resistant to wear and corrosion as well as temperature changes, hence ensuring a long period of service under given conditions. The high strength and accurate design enable the handling of high pressure as well as a large scope of fluids in various processes, making it ideal for chemicals, petrochemical, pharmaceutical, and water treatment industries.

The Single Cartridge Seal US 5008 is easy to install and requires minimal maintenance. It enhances the operational efficiency of equipment while ensuring safety and performance. It is a cost-effective solution for optimizing equipment longevity and maintaining operational integrity.

Features

- Stationary spring design

- Tolerates pressure reversal

- Identical monolithic faces

- Compact design

- Fits on standard bore pumps

- Big bore version available

- Easy to install

- Site repairable

Operating Range

- Pressure : Upto 6kg

- Size: 25mm to 200mm

- Temperature : - 40°C to 280°C (Depending upon Elastomer)

- Speed : 2900 rpm

Materials

- Metal Parts : SS316, SS316L, CD4MCU, Hast-C, Alloy-20

- Elastomers : Viton, Nitrile, Neoprene, Aflas, Silicon, EPR, PTFE, FFKM, STV

- Rotary Face : SiC, Carbon

- Stationary Face : SiC, TC, Carbon

Products FAQ`s

Mechanical seals are devices that prevent the leakage of fluids (liquids or gases) between a rotating shaft and a stationary element in equipment such as pumps, compressors, and mixers. They improve the operation efficiency, reduce costs on maintenance, and provide long equipment life by keeping out contaminants and maintaining the process integrity.

The choice of a mechanical seal depends on factors such as the type of equipment, fluid properties (temperature, pressure, and nature), application conditions, and industry standards. Our team provides detailed application engineering support to recommend the best solution tailored to your needs.

Depending upon operating conditions, material compatibility, and maintenance practices, the service life of a mechanical seal will vary. In optimal operating conditions, our seals have been designed to deliver reliable performance over time. In-service inspection and proper installation are also used to enhance service life.

Yes, we specialize in designing and manufacturing custom mechanical seals to meet a specific application requirement. On top of that, experts are available for troubleshooting serious sealing problems to ensure smooth-running operation.